In a significant development that could reshape the cybersecurity landscape of industrial control systems (ICS), a team of researchers from the Georgia Institute of Technology has unveiled a novel form of malware targeting Programmable Logic Controllers (PLCs). The study, led by Ryan Pickren, Tohid Shekari, Saman Zonouz, and Raheem Beyah, presents a comprehensive analysis of Web-Based PLC (WB PLC) malware, a sophisticated attack strategy exploiting the web applications hosted on PLCs. This emerging threat underscores the evolving challenges in securing critical infrastructure against cyberattacks.

PLCs are the backbone of modern industrial operations, controlling everything from water treatment facilities to manufacturing plants. Traditionally, PLCs have been considered secure due to their isolated operational environments. However, the integration of web technologies for ease of access and monitoring has opened new avenues for cyber threats.

Based on the research several attack methods targeting Programmable Logic Controllers (PLCs) have been identified. These methods range from traditional strategies focusing on control logic and firmware manipulation to more innovative approaches exploiting web-based interfaces. Here’s an overview of the known attack methods for PLCs:

Traditional Attack Methods

Traditional PLC (Programmable Logic Controller) malware targets the operational aspects of industrial control systems (ICS), aiming to manipulate or disrupt the physical processes controlled by PLCs. These attacks have historically focused on two main areas: control logic manipulation and firmware modification. While effective in certain scenarios, these traditional attack methods come with significant shortcomings that limit their applicability and impact.

Control Logic Manipulation

This method involves injecting or altering the control logic of a PLC. Control logic is the set of instructions that PLCs follow to monitor and control machinery and processes. Malicious modifications can cause the PLC to behave in unintended ways, potentially leading to physical damage or disruption of industrial operations.

Shortcomings:

- Access Requirements: Successfully modifying control logic typically requires network access to the PLC or physical access to the engineering workstation used to program the PLC. This can be a significant barrier if robust network security measures are in place.

- Vendor-Specific Knowledge: Each PLC vendor may use different programming languages and development environments for control logic. Attackers often need detailed knowledge of these specifics, making it harder to develop a one-size-fits-all attack.

- Detection Risk: Changes to control logic can sometimes be detected by operators or security systems monitoring the PLC’s operation, especially if the alterations lead to noticeable changes in process behavior.

Firmware Modification

Firmware in a PLC provides the low-level control functions for the device, including interfacing with the control logic and managing hardware operations. Modifying the firmware can give attackers deep control over the PLC, allowing them to bypass safety checks, alter process controls, or hide malicious activities.

Shortcomings:

- Complexity and Risk: Developing malicious firmware requires a deep understanding of the PLC’s hardware and software architecture. There’s also a risk of “bricking” the device if the modified firmware doesn’t function correctly, which could alert victims to the tampering.

- Physical Access: In many cases, modifying firmware requires physical access to the PLC, which may not be feasible in secure or monitored industrial environments.

- Platform Dependence: Firmware is highly specific to the hardware of a particular PLC model. An attack that targets one model’s firmware might not work on another, limiting the scalability of firmware-based attacks.

General Shortcomings of Traditional PLC Malware

- Isolation and Segmentation: Many industrial networks are segmented or isolated from corporate IT networks and the internet, making remote attacks more challenging.

- Evolving Security Practices: As awareness of cybersecurity threats to industrial systems grows, organizations are implementing more robust security measures, including regular patching, network monitoring, and application whitelisting, which can mitigate the risk of traditional PLC malware.

- Limited Persistence: Traditional malware attacks on PLCs can often be mitigated by resetting the device to its factory settings or reprogramming the control logic, although this might not always be straightforward or without operational impact.

In response to these shortcomings, attackers are continually evolving their methods. The emergence of web-based attack vectors, as discussed in recent research, represents an adaptation to the changing security landscape, exploiting the increased connectivity and functionality of modern PLCs to bypass traditional defenses.

Web-based Attack Methods

The integration of web technologies into Programmable Logic Controllers (PLCs) marks a significant evolution in the landscape of industrial control systems (ICS). This trend towards embedding web servers in PLCs has transformed how these devices are interacted with, monitored, and controlled. Emerging PLC web applications offer numerous advantages, such as ease of access, improved user interfaces, and enhanced functionality. However, they also introduce new security concerns unique to the industrial control environment. Here’s an overview of the emergence of PLC web applications, their benefits, and the security implications they bring.

Advantages of PLC Web Applications

- Remote Accessibility: Web applications allow for remote access to PLCs through standard web browsers, enabling engineers and operators to monitor and control industrial processes from anywhere, provided they have internet access.

- User-Friendly Interfaces: The use of web technologies enables the development of more intuitive and visually appealing user interfaces, making it easier for users to interact with the PLC and understand complex process information.

- Customization and Flexibility: Web applications can be customized to meet specific operational needs, offering flexibility in how data is presented and how control functions are implemented.

- Integration with Other Systems: Web-based PLCs can more easily integrate with other IT and operational technology (OT) systems, facilitating data exchange and enabling more sophisticated automation and analysis capabilities.

- Reduced Need for Specialized Software: Unlike traditional PLCs, which often require proprietary software for programming and interaction, web-based PLCs can be accessed and programmed using standard web browsers, reducing the need for specialized software installations.

Security Implications

While the benefits of web-based PLC applications are clear, they also introduce several security concerns that must be addressed:

- Increased Attack Surface: Embedding web servers in PLCs increases the attack surface, making them more accessible to potential attackers. This accessibility can be exploited to gain unauthorized access or to launch attacks against the PLC and the industrial processes it controls.

- Web Vulnerabilities: PLC web applications are susceptible to common web vulnerabilities, such as cross-site scripting (XSS), SQL injection, and cross-site request forgery (CSRF). These vulnerabilities can be exploited to manipulate PLC operations or to gain access to sensitive information.

- Authentication and Authorization Issues: Inadequate authentication and authorization mechanisms can lead to unauthorized access to PLC web applications. Ensuring robust access control is critical to prevent unauthorized actions that could disrupt industrial processes.

- Firmware and Software Updates: Keeping the web server and application software up to date is crucial for security. Vulnerabilities in outdated software can be exploited by attackers, but updating PLCs in an industrial environment can be challenging due to the need for continuous operation.

- Lack of Encryption: Not all PLC web applications use encryption for data transmission, which can expose sensitive information to interception and manipulation. Implementing secure communication protocols like HTTPS is essential for protecting data integrity and confidentiality.

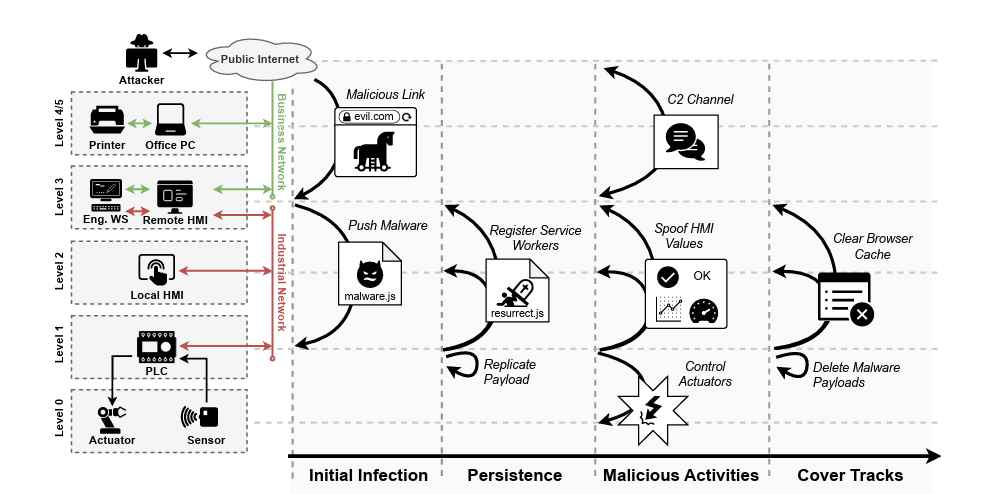

WB PLC MALWARE STAGES

The stages of Web-Based (WB) Programmable Logic Controller (PLC) malware, as presented in the document, encompass a systematic approach to compromise industrial systems using malware deployed through PLCs’ embedded web servers. These stages are designed to infect, persist, conduct malicious activities, and cover tracks without direct system-level compromise. By exploiting vulnerabilities in the web applications hosted by PLCs, the malware can manipulate real-world processes stealthily. This includes falsifying sensor readings, disabling alarms, controlling actuators, and ultimately hiding its presence, thereby posing a significant threat to industrial control systems.

1. Initial Infection

The “Initial Infection” stage of the Web-Based Programmable Logic Controller (WB PLC) malware lifecycle, focuses on the deployment of malicious code into the PLC’s web application environment. This stage is crucial for establishing a foothold within the target system, from which the attacker can launch further operations. Here’s a closer look at the “Initial Infection” stage based on the provided research:

Methods of Initial Infection

The initial infection can be achieved through various means, leveraging both the vulnerabilities in the web applications hosted by PLCs and the broader network environment. Key methods include:

- Malicious User-defined Web Pages (UWPs): Exploiting the functionality that allows users to create custom web pages for monitoring and control purposes. Attackers can upload malicious web pages that contain JavaScript or HTML code designed to execute unauthorized actions or serve as a backdoor for further attacks.

- Cross-Site Scripting (XSS) and Cross-Origin Resource Sharing (CORS) Misconfigurations: Leveraging vulnerabilities in the web application, such as XSS flaws or improperly configured CORS policies, attackers can inject malicious scripts that are executed in the context of a legitimate user’s session. This can lead to unauthorized access or data leakage.

- Social Engineering or Phishing: Utilizing social engineering tactics to trick users into visiting malicious websites or clicking on links that facilitate the injection of malware into the PLC web server. This approach often targets the human element of security, exploiting trust and lack of awareness.

Challenges and Considerations

- Stealth and Evasion: Achieving initial infection without detection is paramount. Attackers must carefully craft their malicious payloads to avoid triggering security mechanisms or alerting system administrators.

- Access and Delivery: The method of delivering the malicious code to the PLC’s web application varies depending on the network configuration, security measures in place, and the specific vulnerabilities of the target system. Attackers may need to conduct reconnaissance to identify the most effective vector for infection.

- Exploiting Specific Vulnerabilities: The effectiveness of the initial infection stage often relies on exploiting specific vulnerabilities within the PLC’s web application or the surrounding network infrastructure. This requires up-to-date knowledge of existing flaws and the ability to quickly adapt to new vulnerabilities as they are discovered.

The “Initial Infection” stage sets the foundation for the subsequent phases of the WB PLC malware lifecycle, enabling attackers to execute malicious activities, establish persistence, and ultimately compromise the integrity and safety of industrial processes. Addressing the vulnerabilities and security gaps that allow for initial infection is critical for protecting industrial control systems from such sophisticated threats.

2. Persistence

The research outlines several techniques that WB PLC malware can use to achieve persistence within the PLC’s web environment:

- Modifying Web Server Configuration: The malware may alter the web server’s settings on the PLC to ensure that the malicious code is automatically loaded each time the web application is accessed. This could involve changing startup files or manipulating the web server’s behavior to serve the malicious content as part of the legitimate web application.

- Exploiting Web Application Vulnerabilities: If the PLC’s web application contains vulnerabilities, the malware can exploit these to re-infect the system periodically. For example, vulnerabilities that allow for unauthorized file upload or remote code execution can be used by the malware to ensure its persistence.

- Using Web Storage Mechanisms: Modern web applications can utilize various web storage mechanisms, such as HTML5 local storage or session storage, to store data on the client side. The malware can leverage these storage options to keep malicious payloads or scripts within the browser environment, ensuring they are executed whenever the PLC’s web application is accessed.

- Registering Service Workers: Service workers are scripts that the browser runs in the background, separate from a web page, opening the door to features that don’t need a web page or user interaction. Malicious service workers can be registered by the malware to intercept and manipulate network requests, cache malicious resources, or perform tasks that help maintain the malware’s presence.

3. Malicious Activities

In the context of the research on Web-Based Programmable Logic Controller (WB PLC) malware, the “Malicious Activities” stage is crucial as it represents the execution of the attacker’s primary objectives within the compromised industrial control system (ICS). This stage leverages the initial foothold established by the malware in the PLC’s web application environment to carry out actions that can disrupt operations, cause physical damage, or exfiltrate sensitive data. Based on the information provided in the research, here’s an overview of the types of malicious activities that can be conducted during this stage:

Manipulation of Industrial Processes

The malware can issue unauthorized commands to the PLC, altering the control logic that governs industrial processes. This could involve changing set points, disabling alarms, or manipulating actuators and sensors. Such actions can lead to unsafe operating conditions, equipment damage, or unanticipated downtime. The ability to manipulate processes directly through the PLC’s web application interfaces provides a stealthy means of affecting physical operations without the need for direct modifications to the control logic or firmware.

Data Exfiltration

Another key activity involves stealing sensitive information from the PLC or the broader ICS network. This could include proprietary process information, operational data, or credentials that provide further access within the ICS environment. The malware can leverage the web application’s connectivity to transmit this data to external locations controlled by the attacker. Data exfiltration poses significant risks, including intellectual property theft, privacy breaches, and compliance violations.

Lateral Movement and Propagation

WB PLC malware can also serve as a pivot point for attacking additional systems within the ICS network. By exploiting the interconnected nature of modern ICS environments, the malware can spread to other PLCs, human-machine interfaces (HMIs), engineering workstations, or even IT systems. This propagation can amplify the impact of the attack, enabling the attacker to gain broader control over the ICS or to launch coordinated actions across multiple devices.

Sabotage and Disruption

The ultimate goal of many attacks on ICS environments is to cause physical sabotage or to disrupt critical operations. By carefully timing malicious actions or by targeting specific components of the industrial process, attackers can achieve significant impacts with potentially catastrophic consequences. This could include causing equipment to fail, triggering safety incidents, or halting production lines.

The “Malicious Activities” stage of WB PLC malware highlights the potential for significant harm to industrial operations through the exploitation of web-based interfaces on PLCs. The research underscores the importance of securing these interfaces and implementing robust detection mechanisms to identify and mitigate such threats before they can cause damage.

4. Cover Tracks

To ensure the longevity of the attack and to avoid detection by security systems or network administrators, the WB PLC malware includes mechanisms to cover its tracks:

- Deleting Logs: Any logs or records that could indicate malicious activities or the presence of the malware are deleted or modified. This makes it more difficult for forensic investigations to trace the origin or nature of the attack.

- Masquerading Network Traffic: The malware’s network communication is designed to mimic legitimate traffic patterns. This helps the malware evade detection by network monitoring tools that look for anomalies or known malicious signatures.

- Self-Deletion: In scenarios where the malware detects the risk of discovery, it may remove itself from the compromised system. This self-deletion mechanism is designed to prevent the analysis of the malware, thereby obscuring the attackers’ techniques and intentions.

The “Cover Tracks” stage is essential for the malware to maintain its presence within the compromised system without alerting the victims to its existence. By effectively erasing evidence of its activities and blending in with normal network traffic, the malware aims to sustain its operations and avoid remediation efforts.

Evaluation and Impact

The researchers conducted a thorough evaluation of the WB PLC malware in a controlled testbed, simulating an industrial environment. Their findings reveal the malware’s potential to cause significant disruption to industrial operations, highlighting the need for robust security measures. The study also emphasizes the malware’s adaptability, capable of targeting various PLC models widely used across different sectors.

Countermeasures and Mitigations

The research paper inherently suggests the need for robust security measures to protect against the novel threat of Web-Based PLC (WB PLC) malware. Drawing from general cybersecurity practices and the unique challenges posed by WB PLC malware, here are potential countermeasures and mitigations that could be inferred to protect industrial control systems (ICS):

1. Regular Security Audits and Vulnerability Assessments

Conduct comprehensive security audits and vulnerability assessments of PLCs and their web applications to identify and remediate potential vulnerabilities before they can be exploited by attackers.

2. Update and Patch Management

Ensure that PLCs, their embedded web servers, and any associated software are kept up-to-date with the latest security patches and firmware updates provided by the manufacturers.

3. Network Segmentation and Firewalling

Implement network segmentation to separate critical ICS networks from corporate IT networks and the internet. Use firewalls to control and monitor traffic between different network segments, especially traffic to and from PLCs.

4. Secure Web Application Development Practices

Adopt secure coding practices for the development of PLC web applications. This includes input validation, output encoding, and the use of security headers to mitigate common web vulnerabilities such as cross-site scripting (XSS) and cross-site request forgery (CSRF).

5. Strong Authentication and Authorization

Implement strong authentication mechanisms for accessing PLC web applications, including multi-factor authentication (MFA) where possible. Ensure that authorization controls are in place to limit access based on the principle of least privilege.

6. Encryption of Data in Transit and at Rest

Use encryption to protect sensitive data transmitted between PLCs and clients, as well as data stored on the PLCs. This includes the use of HTTPS for web applications and secure protocols for any remote access.

7. Intrusion Detection and Monitoring

Deploy intrusion detection systems (IDS) and continuous monitoring solutions to detect and alert on suspicious activities or anomalies in ICS networks, including potential indicators of WB PLC malware infection.

8. Security Awareness and Training

Provide security awareness training for ICS operators and engineers to recognize phishing attempts and other social engineering tactics that could be used to initiate a WB PLC malware attack.

9. Incident Response and Recovery Plans

Develop and maintain an incident response plan that includes procedures for responding to and recovering from a WB PLC malware infection. This should include the ability to quickly isolate affected systems, eradicate the malware, and restore operations from clean backups.

10. Vendor Collaboration and Information Sharing

Collaborate with PLC vendors and participate in information-sharing communities to stay informed about new vulnerabilities, malware threats, and best practices for securing ICS environments.

Implementing these countermeasures and mitigations can significantly reduce the risk of WB PLC malware infections and enhance the overall security posture of industrial control systems.

Information security specialist, currently working as risk infrastructure specialist & investigator.

15 years of experience in risk and control process, security audit support, business continuity design and support, workgroup management and information security standards.